I am an anodizing expert exclusively for aluminum. While you can also anodize other metals such as magnesium and titanium, I have dedicated my career to becoming an expert in anodizing aluminum. There is a reason for that: early on, I realized the environmental benefits of anodized aluminum.

The environmental benefits of anodized aluminum are two-fold. First, anodizing prolongs the lifetime of aluminum products by making them corrosion-resistant and wear-resistant. Second, aluminum can be – in theory – infinitely recycled. In this blog post, I will dive into the intricacies of sustainable aluminum and how to make better choices for your product and the environment.

Sustainable aluminum: reduction vs. recycling

To make the aluminum industry more sustainable, OEMs, designers, and engineers need to understand the implications of reduction and recycling. Reduction refers to reducing the CO2 footprint in production of primary aluminum in various steps of the primary aluminum production. Recycling refers to remelting of used aluminum scrap (secondary aluminum).

CO2 reduction – making aluminum more sustainable

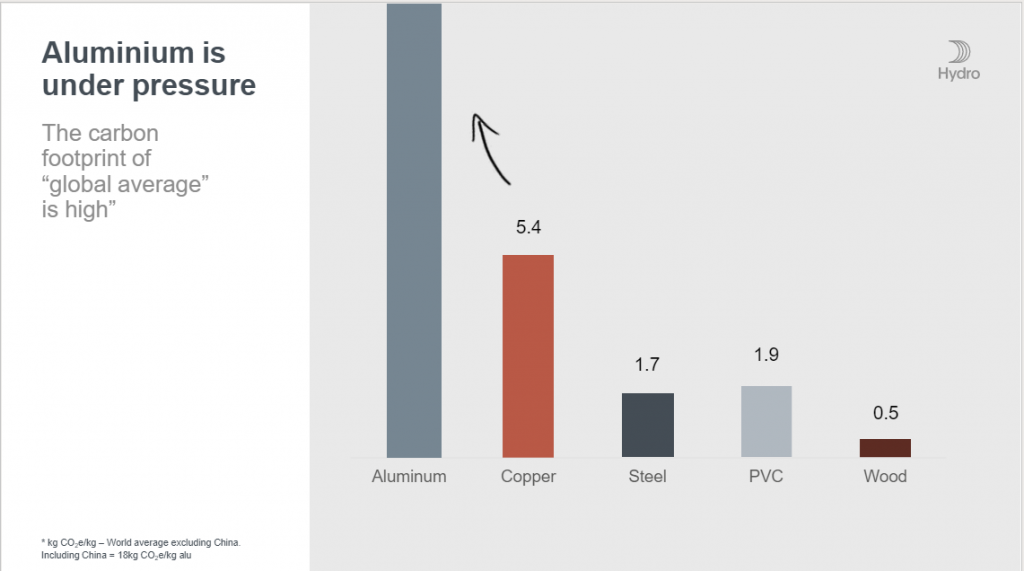

Primary aluminum is also called “virgin” aluminum, meaning that it was extracted from bauxite and then refined into aluminum. In comparison to other materials like copper, steel, or wood, the CO2 emission of primary aluminum production is unreasonably high. Looking at these numbers, it may seem like aluminum is a less sustainable material choice. However, not all aluminum is the same. The most important difference lies in how the primary aluminum has been produced.

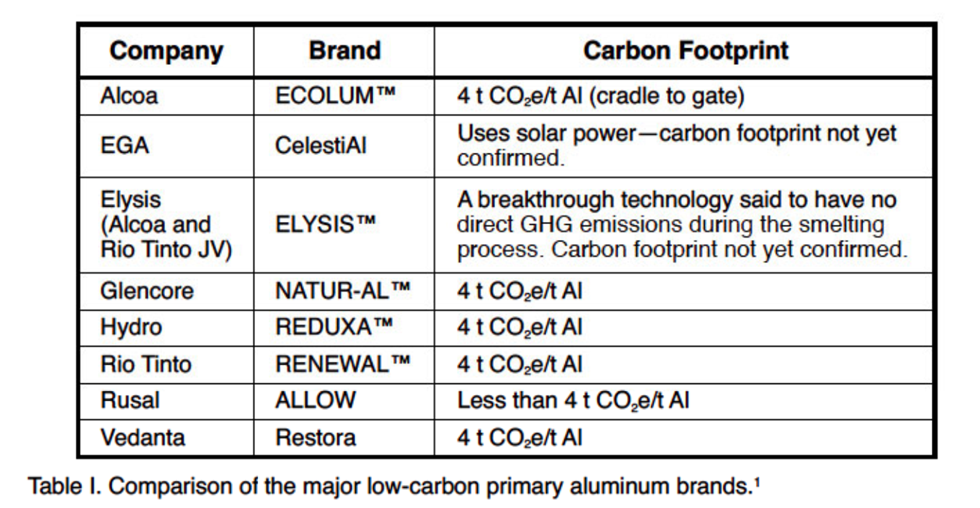

While the primary production of aluminum is highly energy-consuming, recycling aluminum costs only 5% of that energy. The clear conclusion would seem to be to avoid primary aluminum. Yet, even primary aluminum can be a sustainable choice if it was processed with low carbon footprint energy, such as water, wind, solar, or another sustainable power source instead of coal. A lot of aluminum smelters have started to produce primary aluminum with new or improved methods, including the use of hydroelectricity or solar power or the implementation of new processing technologies (Table 1).

Recycling – making aluminum more sustainable

Aluminum is the second most used metal in the world after steel with a global market of around 64 million tons and with a recycled aluminum production of around 12 million tons in 2018. For many years, aluminum recycling was all about used beverage cans. Now all types of scrap materials need to be and are recycled, including both pre-consumer scrap and post-consumer scrap.

Pre-consumer scrap, also called production scrap or process scrap, refers to aluminum waste that comes directly from the production of cast, semi-finished, or finished products. These scrap materials are easy to recycle because the aluminum has neither been painted or coated nor joined or assembled with other materials. In other words, it is still the original aluminum alloy.

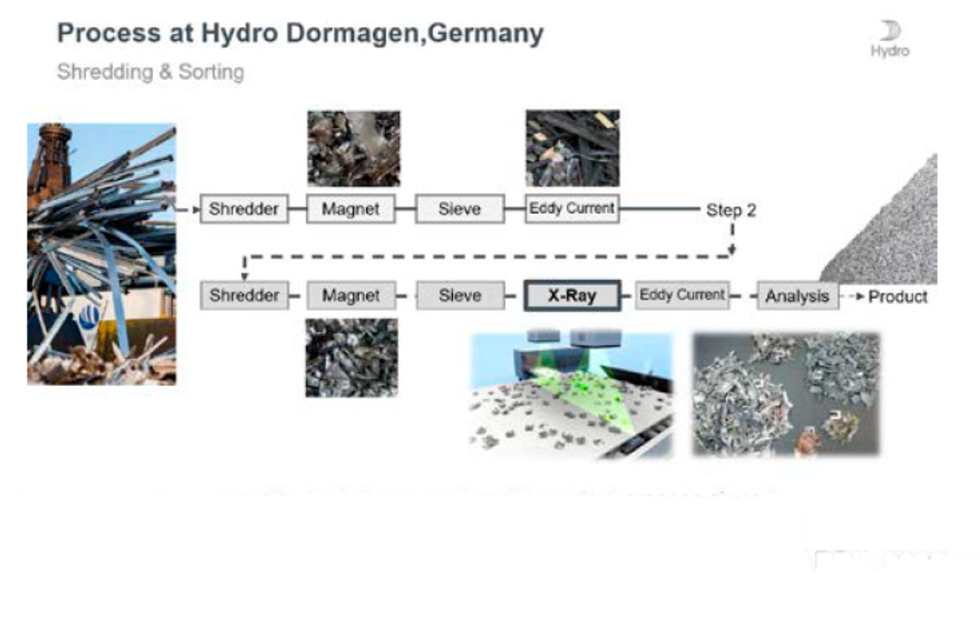

Post-consumer scrap refers to aluminum products that have been used and are ready for disposal, recycling, or reuse. The recycling of post-consumer scrap is lower than pre-consumer scrap, as it presents two main difficulties. First, the recycling of post-consumer scrap is a complex process with many steps, including collection, inspection, separation, shredding, and decoating prior to remelting (Figure 1).

Second, the aluminum scrap also needs to be analyzed (using X-ray or other methods) to determine the alloy elements and separate them, as different types of alloys should not be remelted together in order to avoid a loss of quality. However, this sorting process is still not commonly used.

Choosing more sustainable aluminum

With the growing need for sustainable products and production processes, anodized aluminum provides great opportunities to make more environmentally conscious decisions. While the anodizing process is already inherently environmentally friendly, there are still several choices to make to ensure a more sustainable supply chain and final product. Most importantly, primary aluminum with a low carbon footprint or recycled aluminum should be chosen over conventional primary aluminum.

Do you want to learn more about the sustainable aspects of anodized aluminum?

Then join my live course “5 mistakes to avoid when using recycled anodized aluminum“ in 2023!

Get on the waiting list for the course by typing your info in the form below.

We’ll make sure to notify you when the date is official.

You’ll also sign up to AluConsult’s newsletter with knowledge, tips and offers that help you get better anodized aluminum parts. You can (of course) unsubscribe at any time.