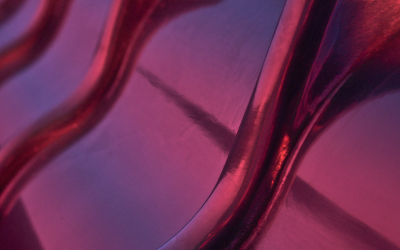

The world is shifting towards sustainable transformation and so is the aluminum industry. As an OEM, engineer, or designer, you might find making your products more environmentally friendly challenging. In this blog post, I will share tips on how to make your anodized aluminum product more sustainable.

Why anodizing is a sustainable surface treatment

Anodizing is one of the most environmentally-friendly surface treatments for aluminum. Alternative coatings, such as paint, can dramatically reduce the ability to recycle aluminum. Moreover, paints, plastics, and plating rely on problematic materials such as organic solvents or heavy metals that can compromise the recyclability of aluminum. In comparison, anodized aluminum is “recycle-neutral”.

Let’s look at the anodizing process to understand why anodizing does not require organic solvents. Anodizing is an electrochemical process that creates an aluminum oxide layer. The anodic coating is generated from the base metal in a water-based process using an electrical current. This means the anodized layer consists of ultra-thin, nontoxic aluminum oxide similar to the layer that naturally forms when aluminum gets in contact with air. Thus, anodizing not only makes aluminum more durable but also ensures its recyclability as no extra material is added to the surface.

To better understand the anodizing process, read this blog post.

Four requirements for sustainable aluminum anodizing

While anodizing is a “green” surface treatment by default, certain aspects can make the anodizing process more or less environmentally friendly. As OEMs and product manufacturers consider the whole supply chain in their sustainability measures, the following requirements should be specified when producing a sustainable anodized aluminum product.

1. Specifying Alloys

Already before the anodizing process, alloy selection is a key aspect of ensuring a proper anodized coating. Alloys made from primary aluminum (regardless of their carbon footprint) generally have low impurities. However, alloys made from recycled post-consumer scrap are at greater risk of containing iron, copper, and zinc impurities at a higher level than normal.

Increased amounts of iron will lead to darkening of the anodic coating and a decrease in corrosion resistance in connection with other alloying elements. An increase in zinc can result in spangling of the surface during the etching process. Higher content of copper and zinc can lead to intergranular corrosion (IGC). Therefore, you must ensure that the recycled aluminum alloys contain low impurity levels. Finally, let your anodizer know, which alloys they will be working with.

2. Anodizing

The anodizing process step is driven by an electrical current, and the amount of electric charge (coulomb) that passes through the aluminum will decide the thickness of the formed anodic layer. Therefore, a current-controlled method will make the anodizing process more efficient compared to using voltage control. Moreover, using pulse anodizing decreases the process time by half, making the process even more efficient.1 Thus, to ensure an energy-efficient process, anodizers should agree to perform current-controlled anodizing and, if the equipment is available, also use pulse anodizing.

3. Coloring

The coloring step is a key aspect of what makes anodizing much more attractive and sustainable than other surface treatments, such as paint or coatings. Paints can chip and peel due to poor production, weather conditions, or abrasion, which decreases the lifetime of the product.

More importantly, paint, coatings, lacquer, and other organic coatings make recycling more difficult, as they have to be thermally removed prior to remelting and are partly responsible for dross formation during melting. Investigations have shown there is a link between metal loss caused by dross and the organic contamination of aluminum.2

The thermal decoating process used to remove the organic contamination results in waste products, such as tar, char, and gaseous fuel vapors that release CO2 into the atmosphere. Thus, choosing anodizing for the colored appearance is the more environmentally-friendly choice. However, in order to ensure that the coloring process remains sustainable, it is important to choose an anodizer that does not use hexavalent chrome as part of its coloring chemicals.

4. Waste Treatment

The sulfuric acid anodizing process produces two main byproducts that need handling: aluminum hydroxide and degraded sulfuric acid. The U.S. EPA classifies aluminum hydroxide as hazardous, meaning the wastewater from an anodizing line cannot be drained into the municipal wastewater system. When working with anodizing suppliers outside of Europe and the U.S., it is especially important to verify that the anodizer is responsibly handling the wastewater, as regulations in other countries are less strict.

Further, hydroxide and sulfuric acid can be reused in the anodizing process, which reduces waste. If it is not reused, however, the degraded sulfuric acid must also be neutralized before disposal to bring it down to a pH level between six and eight. There are plenty of new anodizing developments using the best available and economically achievable technologies, with some plants going as far as having zero-discharge anodizing lines.

What about pre-treatment & sealing?

It is noteworthy that the pre-treatment and sealing steps in the anodizing process are already environmentally-friendly by default. The pretreatment steps include degreasing, etching, and desmutting. These steps include chemicals (such as sodium hydroxide or acids), water, and heating as their main consumables, with no toxic chemicals. Likewise, most of the sealing methods work without any toxic materials and are also environmentally friendly by nature.

Let’s make anodizing more sustainable!

Discussing aspects of the anodizing process (such as current-controlled anodizing and waste treatment) with anodizing suppliers is a part of taking responsibility for the whole supply chain. With these steps, anodized aluminum becomes part of the climate change solution instead of presenting another problem.

To learn more about how to create more sustainable anodized aluminum products, join my live course!

Sources:

- Juhl, A.D., “Why Pulse Anodizing?,” AAC Conference 2019, Houston, TX

- Gültekin, R. and D. Schröder, “Recycling of contaminated aluminum scrap in Twin-Chamber Melting Furnaces,” ALUMINIUM 2018 Conference, Düsseldorf, Germany.